technology

Manufacturing Process

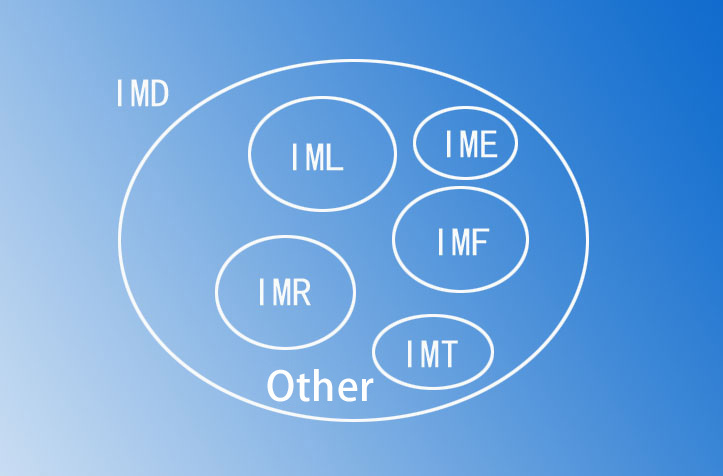

IMD/IML

IMT

IMF

复合板材

INS

IMR

IMD/IML模内注塑(In Molding Label)工艺定义:以表面涂布好工艺要求的PET为载体,在印刷面印刷油墨图案层,粘合剂,油墨固化。再通过加热烘烤做热压成型,切边。将成型好形状的PET通过人工或机械手放入注塑模腔内填充塑胶,高温下粘合剂融化粘合带油墨图案层的PET片材跟塑胶形成一个整体。

technology

Manufacturing Process

IMD/IML

IMT

IMF

复合板材

INS

IMR

IMT process definition: Using PET as a carrier, a release layer, a protective layer, and a printed ink pattern layer are applied to the printing surface, followed by an adhesive and ink curing. The process involves heating and baking for thermal pressing and trimming. The shaped PET is then placed into the injection mold cavity by hand or with a robotic arm, where plastic is filled. At high temperatures, the adhesive melts, bonding the ink pattern layer to the plastic to form a single unit. The workpiece is then removed, and under the action of the release layer, the transparent PET is torn off, transferring the protective layer and ink layer from the original PET onto the plastic, creating a decorative effect.

technology

Manufacturing Process

IMD/IML

IMT

IMF

复合板材

INS

IMR

IMF process: Pre-made 3D stretching forming, using single sheet film operation, with a robotic arm placing it into the mold for injection molding. The film will remain on the surface to form a protective layer.

technology

Manufacturing Process

IMD/IML

IMT

IMF

复合板材

INS

IMR

Product Features: 1. High surface hardness, can reach above 3H; 2. Surface pattern processing usually only allows for simple monochrome patterns; 3. Can present curves through high-pressure molding; 4. Production process yield is not high, and capacity is relatively low; 5. What is the limit value of product thickness?; 6. Overall product cost is higher than IML; high-pressure molds are more expensive.

technology

Manufacturing Process

IMD/IML

IMT

IMF

复合板材

INS

IMR

The INS process involves preheating and softening the INS membrane, which is then formed under high pressure in a sealing cavity. After cooling, excess membrane edges are trimmed away to obtain a molded membrane with embedded features. The embedded molded membrane is placed in the mold cavity for injection molding, resulting in plastic products that have protection and decoration. This is a new process where plastic material is injected and molded in the mold cavity, integrating with the embedded INS membrane, making it particularly suitable for the application of irregularly shaped plastic products.

technology

Manufacturing Process

IMD/IML

IMT

IMF

复合板材

INS

IMR

IMR process: The Chinese name is "In-Mold Decoration". It uses roll-shaped PET as a carrier, sequentially coating its surface with a release layer, a protective layer, a graphic layer, and an adhesive layer to form a transfer film. The transfer film is fed into the mold cavity of an injection molding machine using a film feeding machine. During the molding process of the hot-melt plastic material in the injection molding machine, the adhesive layer melts, allowing the plastic, graphic layer, and protective layer to form an integral whole, separating from the PET carrier film. The surface of the plastic product obtains graphic decoration and protection, achieving a decorative effect.

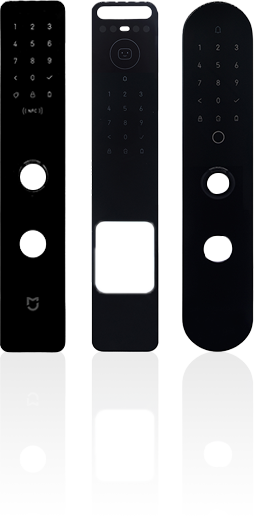

product

Product

Specializing in R & D, production and manufacture of IMD/IML surface decoration products. Such as digital home appliances, mobile phone shell, smart wear, smart door locks, mobile phone protective cover, etc.

SOLUTION

Solution

HeXinSheng IMD/IML process products have very rich surface effects.

Can achieve smooth, frosted, metal texture, drawing, colorful, UV lines, semi-transparent, fully transparent,

Electroplating, color plating, coating, cloth coating and other effects

about us

About HeXinSheng

Shenzhen HeXinSheng Technology Co., Ltd. was established in 2009. The industrial park of the company covers an area of more than 30000 square meters and has a high-precision dust-free workshop. It also has nearly 100 excellent management personnel, 35 engineering and technical personnel, 50 quality personnel, a total of nearly 500 employees, more than 500 injection molding equipment and a monthly production capacity of nearly 15 million pieces; from engineering research and development to mold making, diaphragm printing, diaphragm molding, diaphragm injection molding, inspection and packaging, etc., it has a complete production process.

Industrial Park Area

Number of employees

Monthly production

Injection Molding

Advantage

Core Advantage

cooperation

Partners

Hexinsheng has established a lasting and stable cooperation bond with many high-quality customers. We sincerely invite you to join us and promise that all employees will provide you with high-quality services with a professional attitude and are committed to becoming your trustworthy long-term partner.

Learn More

Blog

Blog

Discoloration effect of IML process is one of the applications of IML process

Discoloration process is also suitable for IML process decorative shell, the common IML process discoloration has two ways: temperature change and night light. Temperature change, as the name implies, changes color when encountering temperature change; night light, that is, ornaments will glow in the night.

2020-04-21

Learn More

The color-changing effect of IML technology is one of the applications of IML technology.

The color-changing process is also applicable to IML (In-Mold Labeling) decorative shells. Common color-changing methods in IML include temperature change and glow-in-the-dark. Temperature change, as the name suggests, changes color in response to temperature variations; glow-in-the-dark means that the decorative piece will emit light in the dark.

2022-04-21

Learn More

High-paying recruitment for Sales Director

II. Industry Field Requirements: 1) Experience in sales of plastic structural parts, hardware stamping, consumer electronics, molds, etc. is acceptable; 2) Experience in sales in the home appliance sector, such as automotive parts, mobile phones, vacuum cleaners, smart door locks, etc. is acceptable; 3) Under 40 years old, with a private car; 4) Vocational school or high school education or above.

2022-11-09

Learn More