101/5000 IMl stands for "Information Management Language" and is commonly used to describe and manage the flow of data and information in information systems.

Release time:

2022-08-20

Source:

What is ML?

IML stands for In Mold Labeling, which literally means "labeling inside the mold". In the injection molding industry, it refers to placing the prepared label (either manually or by machine) into the mold cavity of the injection molding machine, where it fuses with the plastic through injection molding to form the finished IML product.

The materials for labeling can be diverse, such as PET film, PC film, ABS film, PC+PMMA film, leather sheets, bamboo sheets, wood sheets, and a series of thin sheet materials, greatly expanding the imaginative space for product appearance designers. Additionally, product structure designers can design various structures at the bottom of the IML process parts. Therefore, the IML process enriches the decorative effects of the product's surface while also considering structural design, a feature that ordinary injection molding processes cannot achieve.

In addition to the diverse materials and rich effects described above, another important advantage of IML labeling is that it can create three-dimensional shapes through heat pressing or high-pressure forming, allowing the IML finished product's shape and structure to adapt to more design scenarios.

Currently, the most commonly used IML process parts on the market are achieved by fusing plastic films with plastic substrates, incorporating colorful printing or traditional monochrome printing (screen printing) technology to enrich the product's colors and achieve common effects such as full transparency and semi-transparency. Such products can be seen across various industries and are widely used.

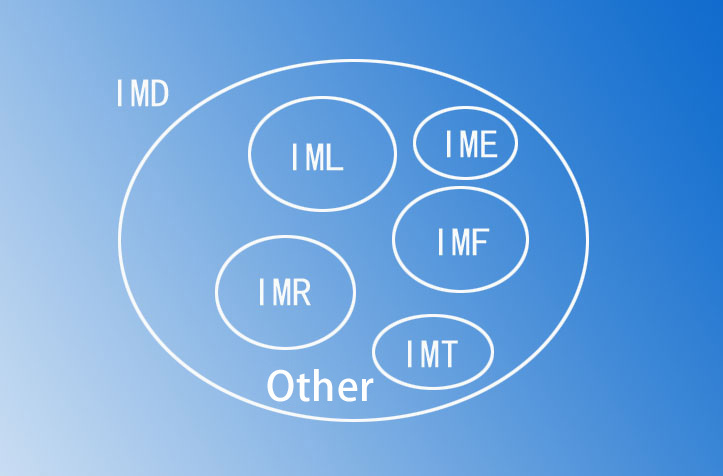

With the innovation and development of IML technology, new processes such as IMT (which retains the IML process while reducing product deformation) and IME (which incorporates circuits into IML parts to achieve electrical functions) have gradually emerged. Each innovative process has its specific suitable application scenarios. In summary, the IML process significantly increases the added value of products compared to traditional injection molding processes.

Next Page

Related News